|

|

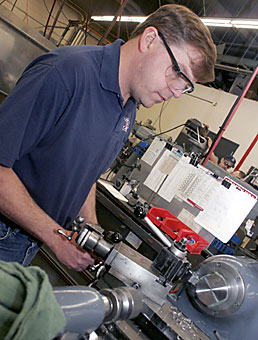

JACOB KONST/Arizona Daily Wildcat

|

Instrument maker Russell Cole forms parts yesterday in the University Research Instrumentation Center. The parts will be used to test out the designs for components for the next Mars mission.

|

|

|

By Cassie Tomlin

Arizona Daily Wildcat

Wednesday, March 30, 2005

Print this

Cut-metal pieces from belt buckles to telescopes

On the west side of the Gould-Simpson building is the noisy but relatively inconspicuous University Research Instrumentation Center.

The large, warehouse-like building houses countless saws, mills, lathes, grinding machines and other gigantic apparatuses which serve URIC's simple goal: to cut metal.

URIC constructs small and large pieces of machines and entire machines, but one thing is consistent - they can make anything.

"Most instrumentation centers have their niche, but we run the whole gamut," said URIC Director Robert Kingsley, who has worked at the center for about 19 years.

URIC instrument makers construct dental tools and telescopes, but most of their works serve the university community.

"We make things for just about every department on the campus," said instrument maker Russell Cole.

URIC operates under the Office of the Vice President for Research and Graduate Studies and is a non-profit organization receiving no state or university funding, with the exception of electricity and heating bills and other such costs.

The Steward Observatory, the Steward Observatory Mirror Laboratory and the chemistry department are regular URIC customers, but Kingsley said URIC once constructed a papermaking machine for the art department.

|

|

It's not often you get to make stuff that goes to another planet.– Russell ColeURIC instrument maker

|

|

On display in the entrance of URIC's fabrication and welding shop are a spectrometer and telescope which were constructed for John Glenn's last trip to space in 1998.

Lyle Broadfoot, senior research scientist in the Lunar Planetary Laboratory, earned a NASA grant to construct the instruments for the flight, Kingsley said.

Broadfoot submitted an initial design to the shop, like anyone employing URIC.

Some plans are as simple as lines on paper and some are specifically dimensioned or already computerized files, depending on the skills of the designer.

The software on the computers connected to the gigantic coordinate measuring metal-cutting machines maps out the tool paths to cut the lines, converting the designs to program codes made up of a series of X's, Y's and numbers telling the mills and lathes where to go.

URIC also uses manual machines, which are cut by cranking a handle, and coordinates are measured without the aid of a computer.

The materials include aluminum, stainless steel, steel, titanium, copper, plastics and any nontoxic material, which are provided with the design, ordered or pulled from the house stock, Kingsley said.

Upon completion, the more precise instruments undergo the test of a $10,000 measuring machine with a tolerance of three ten-thousandths of an inch.

The machine tests length, width, parallelism and concentricity with a needlelike, joystick-controlled probe sliding on air bearings atop a 22,000 pound, 5-by-10-foot granite base.

"It's just like playing video games, to an extent," Kingsley said.

The machine resides in a temperature sensitive 68-degree room so as to avoid heat-induced metal expansion.

The machine's measurements are compared to the initial sketch to test the accuracy of the construction.

If they do not measure up, "they start over," Kingsley said.

URIC operates the $10,000 machine in conjunction with the Steward Observatory, which currently uses the equipment to measure lenses.

Aside from the measurer, mostly all of URIC's machines are 20 years old, the age of the center since it has belonged to the physics laboratory.

Kingsley said URIC employees rebuild and repair the machines as needed instead of buying new ones.

However, he said upkeep is not strenuous as some machines are left unused for a month.

"We're a prototype shop, so we make one, two or three of things, not 10,000 on an assembly line," said Kingsley.

The shop's six instrument makers take on about eight to nine pieces at a time and work on them at various stages of completion.

"I've seen it all," Kingsley said. "And then somebody crosses the threshold and has something made which surprises me."

Cole is currently constructing a torque plate for the Lunar Planetary Lab's Mars Phoenix Lander. The plate is part of a camera and will go on a machine that might travel to Mars in 2007.

"Its not often you get to make stuff that goes to another planet - not everybody can say that," Cole said.

URIC is also constructing a telescope for Iowa State University.

Not all assignments are scientific - the center sometimes makes plaques for awards and can engrave anything.

For an hourly rate, URIC will undertake any task, although Kingsley said he discourages "frivolous" projects.

"If somebody wanted something like (a fork), I would tell them why get it here for $25 when you could get it at a hardware store for $5?" Kingsley said.

Kingsley said URIC employees work eight hours a day, five days a week, and take pride in their product, not their paycheck.

"We're not in here to drive Mercedes-Benzes," Kingsley said of URIC employees. "We're here to support the research institution."